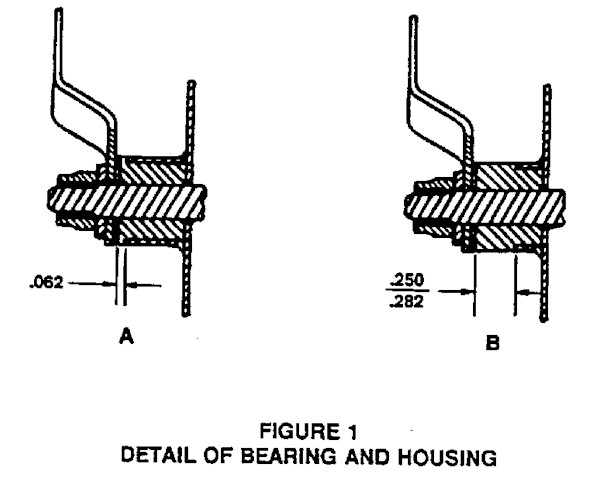

DETAIL OF BEARING AND HOUSING

93-22-05

TELEDYNE CONTINENTAL MOTORS

Amendment 39-8744Docket 93-ANE-54

Applicability: Teledyne Continental Motors (TCM) Model O-200A reciprocating engines with Engine Serial

Numbers 256030 through 256037; and TCM C85, C90, O-200, and O-240 series reciprocating engines

with carburetor air intake housing assemblies, Part Numbers (P/N) CE11141, CE11142, 639814,

639815, 641534, and Repair Kit Assemblies, P/N 641689, purchased after August 31, 1991, without a

permanent ink stamp "CSB 93-13" located on the inside of the housing assembly. These engines are

installed on but not limited to the following aircraft: American Champion Models 7BCM, 7CCM, S7CCM,

7DC, S7DC, 7EC, S7EC, 7FC, 7JC, 7ECA, 11BC, S11BC, 11CC, S11CC, and 402; Anderson

Greenwood Model 14; Cessna Model 120, 140, 140A, 150, 150A-M, and A150K-M; Luscombe Model

8E, 8F, and T-8F; McClish (Funk) Model B85C; Piper Model PA-18 and PA-19; Reims Model F150G, H,

J, K, L, M, FA150K, L, FRA150L, and M; Spinks Model Lark 95; Superior (Culver) Model V and V-2;

Taylorcraft Model 19 and F-19; and Univair (Erco, Forney, Alon, Mooney) Model 415E, 415G, F-1, F-1A,

A-2, and M-10.

Compliance: Required as indicated, unless accomplished previously.

To prevent engine failure due to a cracked air valve in the carburetor air intake housing assembly,

accomplish the following:

(a) Within the next 5 hours time in service (TIS) after the effective date of this AD, inspect the

carburetor air intake housing assembly in accordance with paragraph 2 of the Inspection

Procedure section of TCM Critical Service Bulletin (CSB) No.

93-13, dated August 12, 1993.

(1) If the carburetor air intake housing assembly meets the requirements of Paragraph 2A of the

Inspection Procedures of TCM CSB No. 93-13, dated August 12, 1993, no further action is

required.

(2) If the carburetor air intake housing assembly meets the requirements of paragraph 2B of TCM

CSB No. 93-13, dated August 12, 1993, inspect the carburetor air intake housing assembly

for cracks. If cracks are found anywhere in the assembly, prior to further flight replace with a

serviceable assembly.

(b) Thereafter, for assemblies that meet the requirements of paragraph 2B of TCM

CSB No. 93-13,

dated August 12, 1993, inspect the carburetor air intake housing assembly for cracks in

accordance with Paragraphs 3 and 4 of the Inspection Procedure of TCM CSB No.

93-13, dated

August 12, 1993, at intervals not to exceed 25 hours TIS since the last inspection. If cracks are

found anywhere in the assembly, prior to further flight replace with a serviceable assembly.

(c) Inspect uninstalled carburetor air intake housing assemblies in accordance with paragraph (a) of

this AD prior to installation.

(d) For the purpose of this AD, a serviceable carburetor air intake housing assembly is defined as:

(1) An assembly purchased on or before August 31, 1991; or

(2) An assembly that meets the inspection criteria of paragraph (a)(1) of this AD; or

(3) An assembly with the following P/N's:

(i) 653661, which supersedes CE11142;

(ii) 653670, which supersedes 639815;

(iii) 653675, which supersedes 641534;

(iv) 653657, which supersedes 641689; or

(4) An assembly, P/N 641534, with a permanent ink stamp "CSB

93-13" located on the inside of

the housing assembly.

NOTE

The assemblies, P/N's CE11141 and 639814, have not been superseded, as these are

assemblies with the air filter included, corresponding to airboxes, P/N's CE11142 and 639815.

(e) Replacement with a serviceable carburetor air intake housing assembly constitutes terminating

action to the inspection requirements of this AD.

(f) An alternative method of compliance or adjustment of the compliance time that provides an

acceptable level of safety may be used if approved by the Manager, Atlanta Aircraft Certification

Office. The request should be forwarded through an appropriate FAA Maintenance Inspector,

who may add comments and then send it to the Manager, Atlanta Aircraft Certification Office.

NOTE

Information concerning the existence of approved alternative methods of compliance with this

airworthiness directive, if any, may be obtained from the Atlanta Aircraft Certification Office.

(g) Special flight permits may be issued in accordance with FAR 21.197 and 21.199 to operate the

airplane to a location where the requirements of this AD can be accomplished.

(h) The inspections, and replacement, if necessary, shall be done in accordance with the following

service document:

Document No. Pages Revision Date

TCM CSB No. 93-13 1-3 Original August 12, 1993

Total pages: 3.

This incorporation by reference was approved by the Director of the Federal Register in

accordance with 5 U.S.C. 552(a) and 1 CFR part 51. Copies may be obtained from Teledyne

Continental Motors, P.O. Box 90, Mobile, AL 36601; telephone (205) 438-3411. Copies may be

inspected at the FAA, New England Region, Office of the Assistant Chief Counsel, 12 New

England Executive Park, Burlington, MA; or at the Office of the Federal Register, 800 North

Capitol Street NW., suite 700, Washington, DC.

(i) This amendment becomes effective December 14, 1993, to all persons except those persons to

whom it was made immediately effective by priority letter AD 93-22-05, issued November 4,

1993, which contained the requirements of this amendment.

FOR FURTHER INFORMATION CONTACT:

Jerry Robinette, Aerospace Engineer, Atlanta Aircraft Certification Office, FAA, Small Airplane

Directorate, 1669 Phoenix Parkway, Suite 210C, Atlanta, GA 30349; telephone (404) 991-3810, fax (404)

991-3606.

CRITICAL SERVICE BULLETIN

CSB93-13

Compliance Necessary To Maintain Safety

SUBJECT: CARBURETOR AIR INTAKE HOUSING ASSEMBLY INSPECTION

PURPOSE:

To provide an inspection procedure and replacement instructions for carburetor air intake housing

assemblies.

COMPLIANCE:

Those carburetor air intake housing assemblies, repair kits and engines listed in the MODELS

AFFECTED must be inspected within the next 10 hours and every 25 hours thereafter until replaced with a

current production assembly.

MODELS AFFECTED:

1) C85, C90, O200A & B, and O240 model engines Carburetor Air Intake Housing Assemblies and

P/N 641689 Repair Kit Assemblies that were purchased from TCM between the dates of

September 1, 1991 and June 30, 1993. The Carburetor Air Intake Housing Assembly part

numbers which are affected are: CE11141, CE11142, 639814, 639815 and 641534 as

identified in paragraph 2B of the Inspections Procedures set forth in this bulletin.

2) All new engines identified below.

The engines listed below must be inspected to determine if the affected assemblies are installed. Those

that have affected assemblies installed must be inspected per the Inspection Procedures set forth in this

bulletin.

| MODEL | SERIAL NUMBER |

| NEW ENGINES | |

| O200A | 256030 thru 256037 |

TCM has received reports that the affected carburetor air intake housing assemblies have experienced

cracks in the air valve and in the welds which attach the air valve to the shaft. Therefore, it is necessary to

inspect and replace the affected assemblies in accordance with the following instructions. Affected repair

kits P/N 641689 must be replaced with current production kits.

2 of 3

WARNING

Failure to replace any affected assembly that contains a crack may result in breakage of the air

valve and/or separation of the air valve from its shaft and cause partial or total loss of engine

power.

INSPECTION PROCEDURE

1. Remove engine cowling to gain access to the carburetor air intake housing assembly.

2. Measure the exposed portion of the Teflon bearing. See Figure

1.

A. Those carburetor air intake housing assemblies having an exposed portion of the Teflon

bearing which measures .062 (as shown in Figure 1 A) do not require replacement pursuant

to this bulletin. However, such assemblies should be inspected thoroughly as part of each

100 hour inspection and any discrepancies corrected.

B. Any carburetor air intake housing assembly having an exposed portion of the Teflon bearing

which measures .250 - .282 (as shown in Figure 1 B) must be inspected in accordance with

this bulletin, with repetitive inspections at 25 hour intervals until the assembly is replaced.

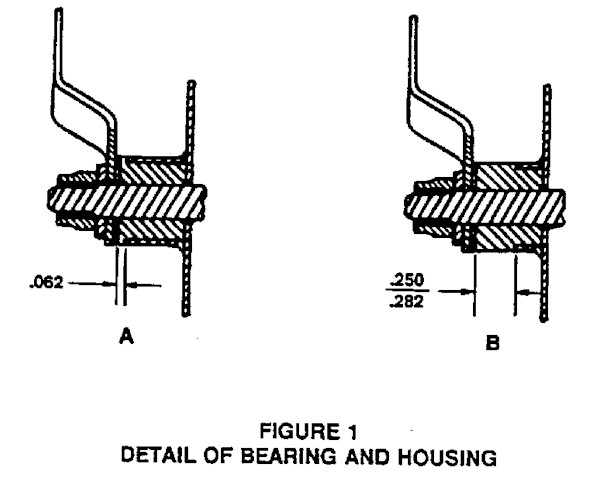

3. Remove the air filter so that the air valve and the welds that attach the air valve to the shaft can be

inspected.

4. Inspect the entire carburetor air intake housing assembly for cracks. Using an inspection mirror

and light, thoroughly inspect the welds that attach the air valve to the shaft and the areas of the air

valve adjacent to the welds for cracks. See Figure 2.

REPLACE THE COMPLETE CARBURETOR AIR INTAKE HOUSING ASSEMBLY BEFORE

FURTHER FLIGHT IF CRACKS ARE FOUND ANYWHERE IN THE ASSEMBLY.

5. Inspect the general condition of the entire carburetor air intake housing assembly. Inspect for

wear on the bushings, shaft and lever. Verify that the air valve operates freely with no binding.

CORRECT ALL DISCREPANCIES BEFORE FURTHER FLIGHT.

6. After the initial inspection has been performed, the repetitive 25 hours inspections can in most

cases be performed without removal of the engine cowling.

REPLACEMENT INSTRUCTIONS

All affected carburetor air intake housing assemblies as identified under paragraph 2B above and P/N

641689 repair kit assemblies purchased between the dates of September 1,1991 and June 30, 1993

must be replaced. Such assemblies may continue in service until replacement assemblies are obtained

provided: (1) they contain no cracks or other discrepancies and, (2) they continue to be inspected at 25

hour intervals in accordance with this bulletin.

A replacement assembly must be ordered from TCM as soon as bulletin affectivity has been established.

Orders will be filled as replacement assemblies become available.

Teledyne Continental Motors will replace all carburetor air intake housing assemblies and repair kits

affected by this bulletin (see paragraph 2B) at no charge on an exchange basis and will allow one (1)

hour labor for removal and installation. Claims may be filed through any TCM distributor.

FIGURE 1

DETAIL OF BEARING AND HOUSING

FIGURE 2

CROSS-SECTION OF AIRBOX

CATEGORY 2

FAA APPROVED

TELEDYNE CONTINENTAL MOTORSP.O BOX 90 · MOBILE, ALABAMA 36601

(205) 438-3411